Rail

We are the world’s preeminent textile partner and supplier to global rail operators.

Made for rail

Our fabrics are found worldwide on high speed intercity and intercontinental train networks, lightrail systems, underground and overground urban transit systems and tramways.

We work in partnership with design houses and network operating companies to create interior textile solutions which not only enhance the passenger experience, but dovetail with corporate identity and interior branding to ensure the upholstery and ancillary trim fabrics are constructed and coloured as a fully cohesive scheme.

Made bespoke

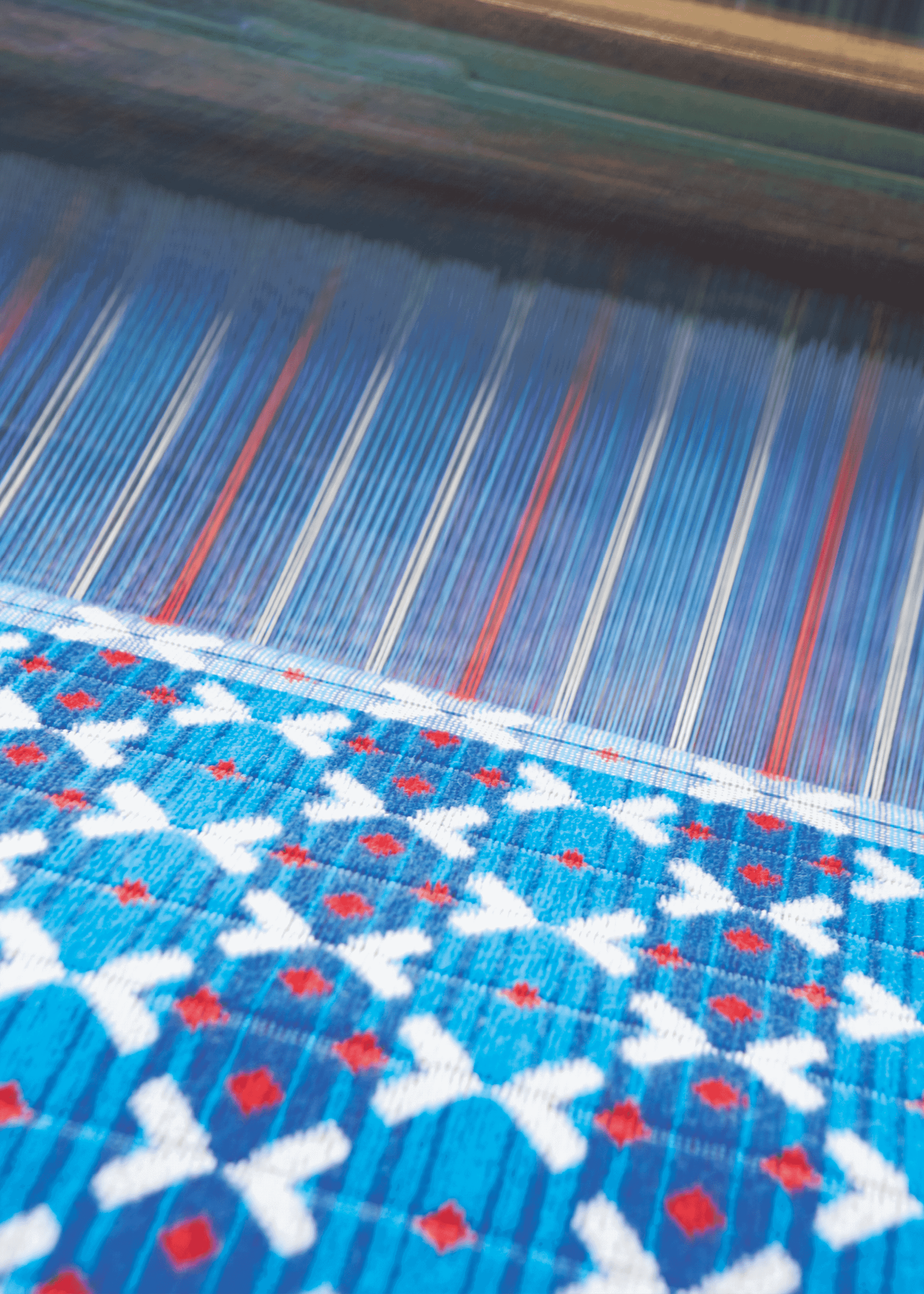

We have unrivalled capabilities across woven options, which are engineered not only for long-lasting durability, but to meet international rail flammability standards to ensure compliance with the strictest health and safety standards.

The vast majority of the fabrics, leather and vinyl we supply into the rail market are custom-made for specific projects, where we work in tandem with design houses and operators – or both – to fulfil a design brief and translate a vision for the railcar interior. Depending on the project, we might be asked to create the fabric for standard class and first class, including priority seating, or a single fabric for a specific line.

We have a talented team in our custom design studio, who are experienced in working collaboratively and consultatively with international customers on high profile global projects where there are multiple stakeholders and complex aesthetic and technical requirements. Whether you’re a textile novice or a seasoned design professional, we’ll give you our total support and put all our textile genius at your disposal.

Learn more about our bespoke woven capability.

Made for safety

In the rail sector, we are recognised as being a leader in global flammability standards, able to engineer our fabrics and specialist FR treatments to meet the most stringent. Flammability performance is highly complex and technical, test for a myriad of different criteria such as ignitability, spread of flame, flaming droplets, heat release, smoke density and smoke toxicity.

We meet a myriad of flammability standards in global regions, including : EN 45545 (Global) and UIC 564-2 App 5 (Europe), BS 5852 Ignition Source 7 (UK) and NFPA 130 (USA). This isn’t an exhaustive list, so if you need to meet a different flammability performance standard, then please do get in touch.

Made by Camira

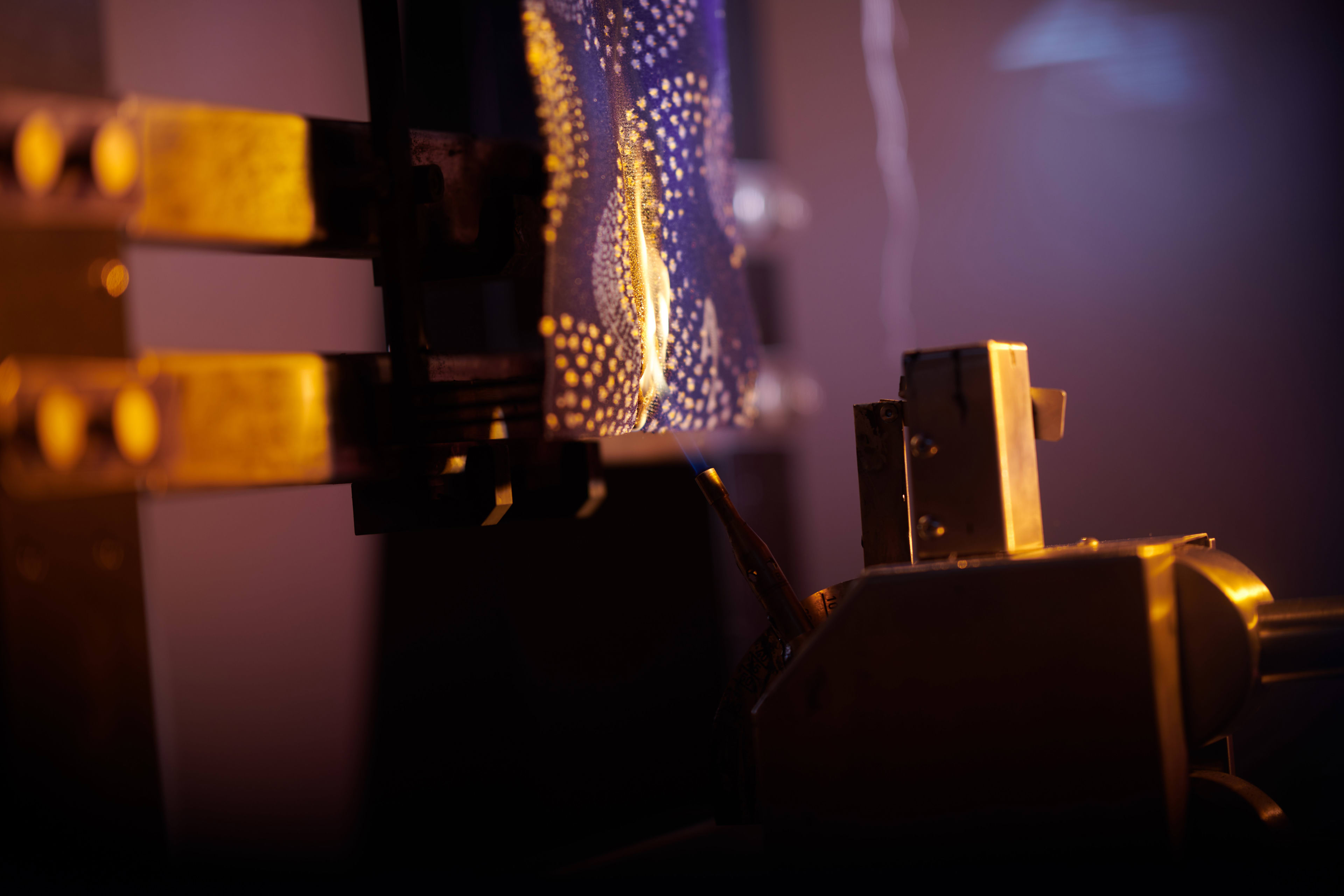

Our in-house manufacturing capabilities span a very wide range of woven constructions on different loom types, as well as digital printing onto woven wool base fabric options for even greater design flexibility. The most popular composition for woven fabrics is 85% wool, 15% polyamide, which is a proven and highly versatile material choice. Our looms can create cut pile fabrics on face-to-face jacquards, all loop pile on wire looms, or a combination of cut and un-cut pile. We also have both dobby and jacquard looms to create flat-cloths in worsted wool in either plain weaves or patterns.

We carry out every step of the manufacturing process at our own production facilities, from yarn dyeing to weaving and final inspection of woven fabric.

Our woven wool base fabrics in cut or loop moquette can also be digitally printed in an innovative process which opens new creative opportunities for branding and on seat messaging. All our fabric constructions can also be combined with high performance leather and vinyl to allow for combination upholstery using a mixture of material types.

Made over hundreds of years

Our expertise is built on over 200 years’ history in transportation textiles though our association with John Holdsworth & Co and the celebrated moquette fabrics which were first made for the steam age of rail travel before the invention of the combustion engine which led to modern day road transport in personal and public vehicles.

So our pedigree extends from wire woven moquette fabrics with cut and loop pile, to all cut plush velour, automotive inspired flat-cloths and performance vinyl and leather. These different constructions and material options give unrivalled design options for the industry, now complemented by innovative digital print capability which brings a new approach to textile creativity and flexibility.

One of the most famous fabrics from the Holdswoth era is the wool rich moquette, Vigor, with its original graffiti inspired patterns making it instantly recognisable and well loved. Another firm favourite is Aura, which has become a contemporary classic, now with 200 design permutations, coloured to connect with performance faux leather Vita and genuine leather Classic. For the most modern, cutting edge look and finish, our latest fabrics are Hybrid and Hybrid Next Gen, designed for the electric age, with automotive inspired smaller scale patterns in an all loop construction with a double density surface which mimics the appearance of a flat woven fabric.

Learn more about our 200 year history.