Effective and efficient, this advanced capability offers the following services:

- Multi-layer, high-speed automated cutting

- Wide range of stitch types

- Logo application and embroidery

- Attachment application, such as zips and eyelets

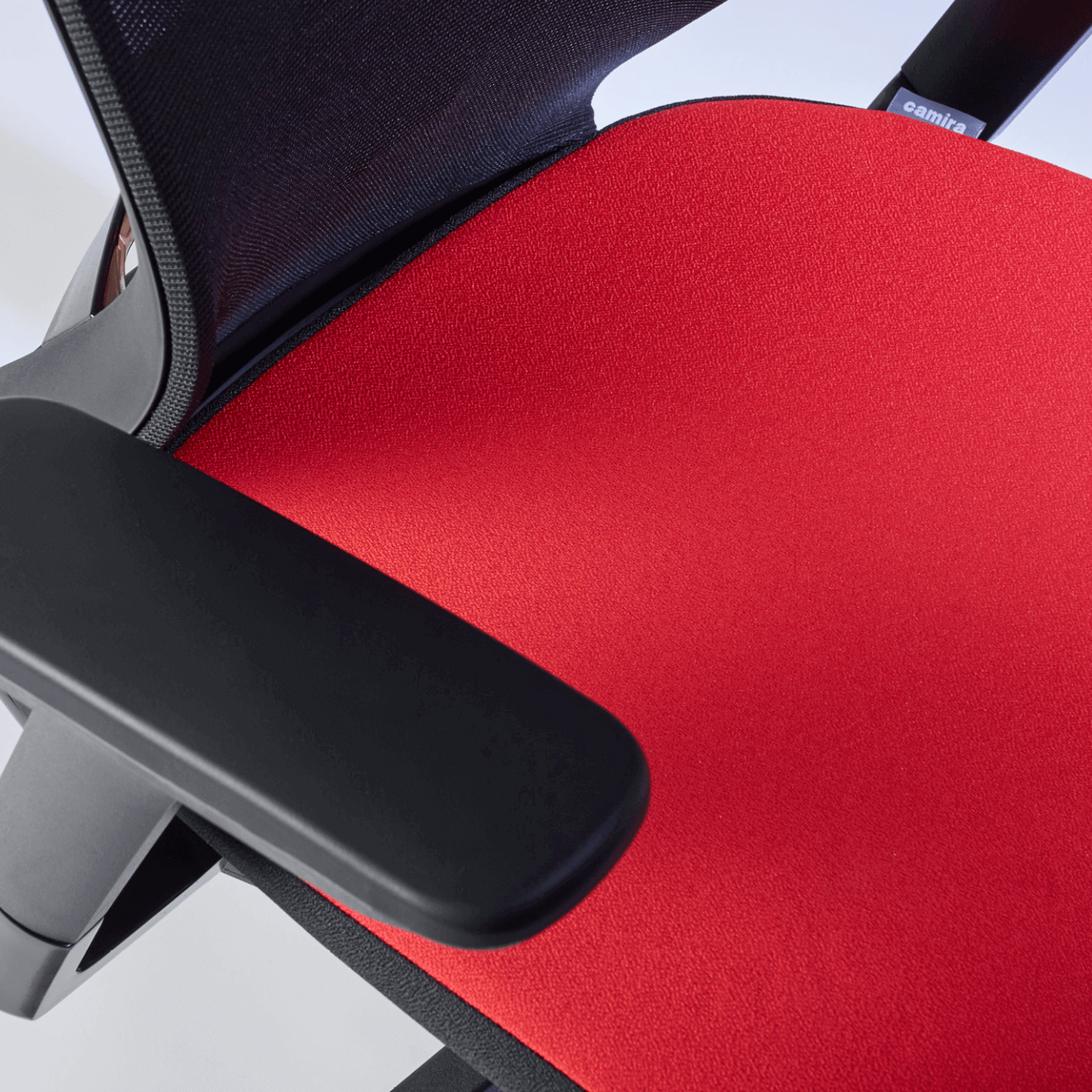

- Ultrasonic welding, bonding fabric to frames

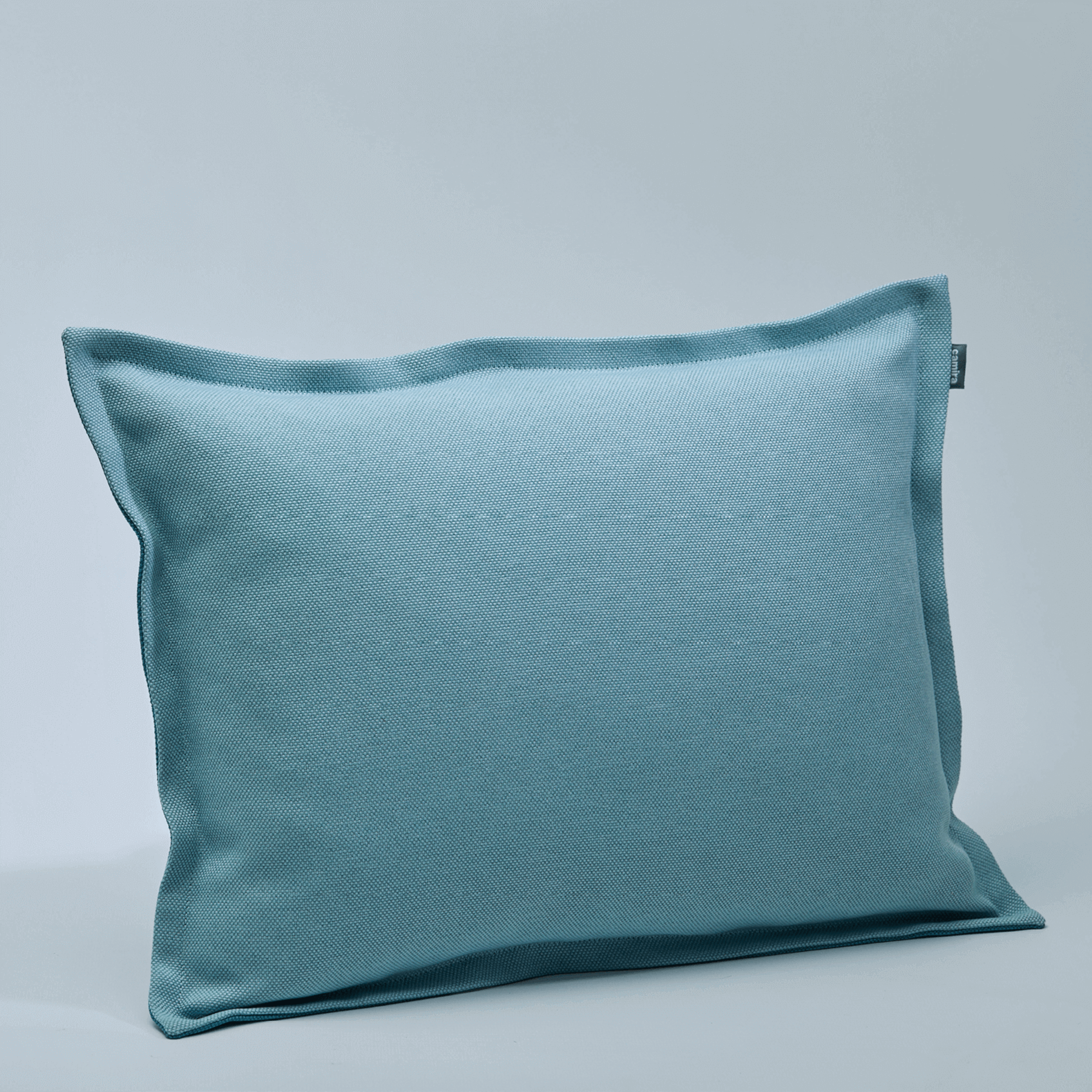

- Ready-to-assemble seat and screen covers